Beams made from Die-cast high grade aluminium alloy flanges are suitable for Airjet, Waterjet & Rapier looms like Toyota, Tsudakoma, Picanol, ITEMA, Dornier, Somet, Sulzer. Weaving machine flange diameters are available from 500mm to 1250mm.

Warper beams are dynamically balanced as per ISO 1940 quality 6.3. The construction is appropriate to the need of Stability, Precision and Speed required by the processing condition. Beam flange diameters are available upto 1400mm.

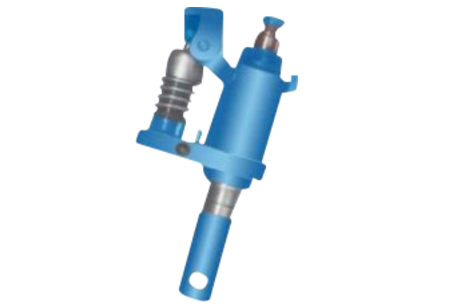

This trolley is useful for transporting warp beam with healds frames. A hydraulic foot pump allows quick lifting of warp beam. A precision valve allows gentle lowering of beam.

This trolley is useful for transporting warp beams. A hydraulic pump allows quick lifting of warp beam. A precision valve allows gentle lowering of beam.

This small and handy trolley offers wide range of applications. This trolley is useful for removing empty beams from the weaving looms and transporting them to the ware house. It offers easy and safe handling of warp beam

This trolley can be easily operated in narrow alley of looms. With hydraulic system of trolley, cloth roll can be easily lifted from the weaving machine. This trolley can be easily maneuvered due to its track wheel system.

This is best solution of space saving and safe storage of warp beams. Beams from 800 mm to 1250 mm flange diameter can be stored in this storage system. It can be designed in 4 layers. A PLC control system helps to select entered beam.

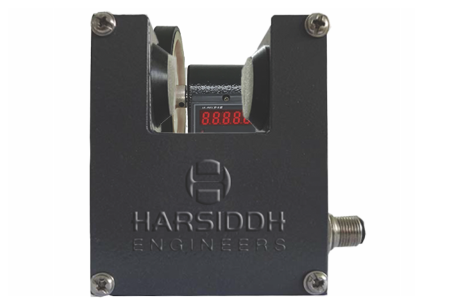

The “Harsiddh” range of fabric inspection has been develop to provide a total solution for textile manufacturers to synchronize fabric inspection at all stages.